Since 2017, we distribute the innovative Degassing system®, produced by BMM Technology, the first to use high vacuum technology to accelerate coffee degassing and the only one, even today, capable of significantly reducing energy consumption and nitrogen requirements throughout the process, from grinding to storage to packaging, always in zero-oxygen conditions.

Coffee degassing

As is well known, during the roasting phase of coffee, many gaseous components are formed together with the aromas and, among them, in large quantities, carbon dioxide that is initially enclosed in the coffee cells slowly gets released outside.

This process must be somehow governed and especially accelerated to prevent residual gases, particularly CO2, from escaping once the coffee has been packaged, risking the top of single-serving capsules to peel off or vacuum bags bulging.

“Natural” degassing is unsuitable for the coffee industry:

- it takes long time;

- it is influenced by climatic and environmental variables;

- it increases the risk of product contact with oxygen, resulting in oxidation and loss of quality.

Nowadays, it is therefore necessary to force and carefully control the process at every stage: from bean delivery to grinding, to feeding the degassing silos, to storage and conservation, to transport to the packaging machines while improving it where possible.

Toasting

Grinding

Degassing

Stockage

Transport

Packaging

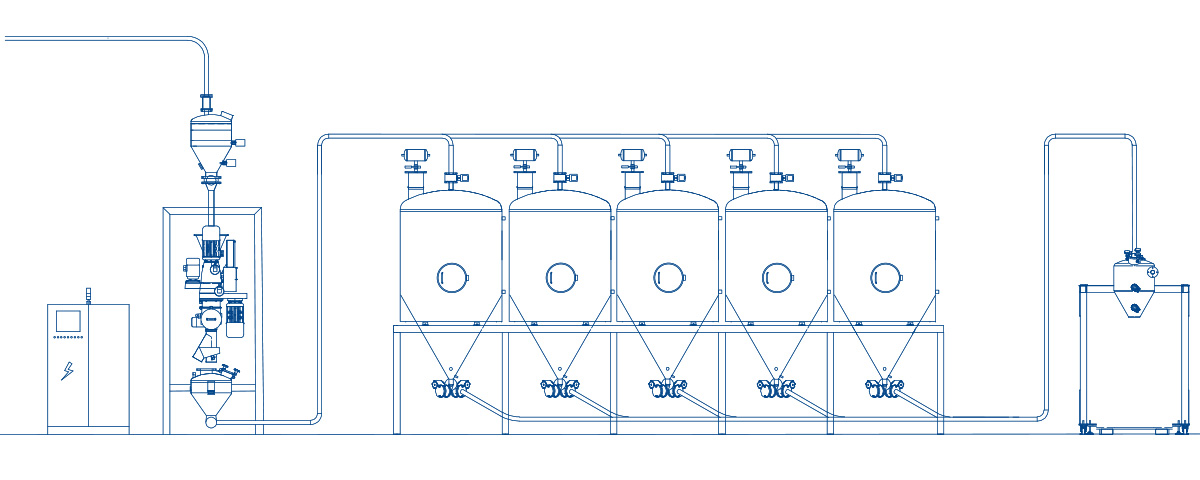

Degassing sistem with MAC5 grinder

Made in Italy

innovation and research

In degassing processes, it is established practice to use nitrogen, an inert gas that does not alter the characteristics of the coffee. However, it has been proven that the simple introduction of nitrogen into the silos does not affect degassing times, but only its conservation.

Accelerating the degassing process

BMM Colombini system is designed to accelerate degassing and to reduce energy consumption and nitrogen requirements throughout the process, from grinding to packaging.

The main innovation introduced by the Degassing system ® was to use the high vacuum, to force the extraction of CO2, and to transport the coffee throughout the production line.

High vacuum, high efficiency,

highest quality

The Degassing system® was the first in the world to use high vacuum technology with very high negative pressures down to -800mbar alternating with over pressure cycles with nitrogen injection (up to +300mbar). The right combination of these two phases accelerates the degassing process, opening the fragile coffee cells sooner, which in this way release CO2 more quickly, saving up to 40% time.

Transportation of ground coffee in a high vacuum

Given its effectiveness, the high vacuum technology was also adopted for transporting the ground coffee, both when loading the silos and transporting it to the packaging machines, increasing efficiency and considerably reducing energy consumption.

For consistently excellent coffee

High vacuum conditions throughout the plant ensure the highest quality of freshly ground coffee:

- no possibility of oxygen contamination, being a completely closed system;

- constant particle size distribution along the entire line, thanks to semi-dense phase handling;

- total absence of residue at the end of the cycle, which allows the processing of multiple mixtures without contamination of different products.

Coffee degassing system with MAC3

Unrivalled energy and cost savings

Our coffee degassing system guarantee financial savings of tens of thousands of euros per year.

Minimal energy consumption

The absence of moving mechanical parts during transport minimizes energy consumption for coffee handling.

Faster degassing

The use of a high vacuum, alternating with high-pressure cycles, allows a 30-40% reduction in degassing time.

Fewer silos used and less space needed

Degassing is faster and consequently, fewer silos are needed for the same production capacity, reducing investment and space occupied

Less nitrogen for degassing

There is no lower nitrogen consumption in the market for the same performance. For example, our system guarantees nitrogen consumption of no more than 5 m3/h in the case of 700 kg silos.

Zero maintenance costs

Transporting coffee by high vacuum, with no moving mechanical parts, minimizes the cost of maintenance and repair of any breakdowns.

Zero nitrogen for storage

Thanks to the high vacuum inside the silo, there is no need for nitrogen during the product storage phase, with further obvious savings.

Unparalleled degassing

Installed plants

50

since 2017

Time

Up to 40% less*

Nitrogen consumption

Up to 95% less*

Operating costs

As much as 10 times less*

*Compared with other coffee degassing systems.

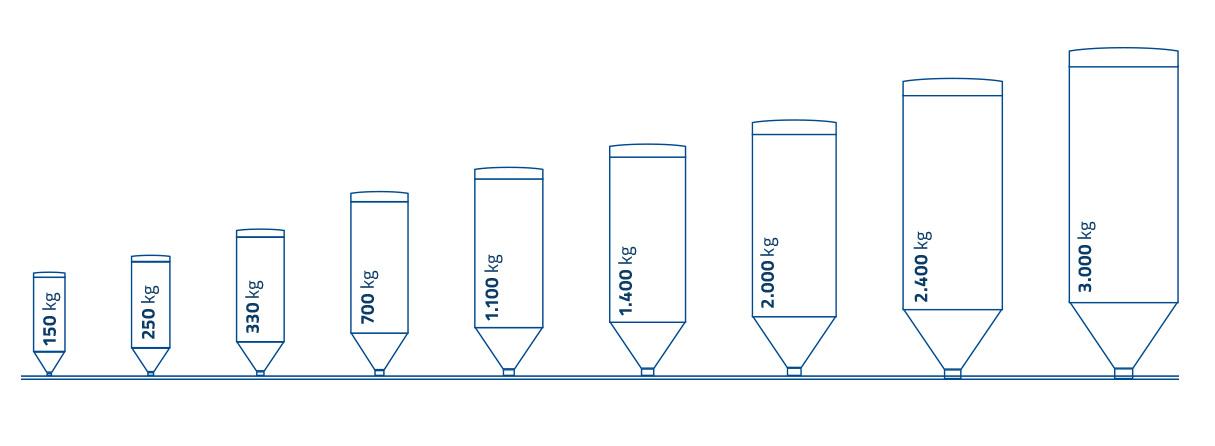

Flexible, modular, taylor-made

The Degassing system® is available in different sizes and adaptable to every production requirement

The available sizes of the silos:

150 / 250 / 330 / 700 / 1100 / 1400 / 2000 / 2400 and 3000 kg.

Gallery: Coffee Degassing System.

Some of our plants installed around the world